Ibhanti yokuhambisa luhlobo lwefriction drive ukuthutha imathiriyeli ngendlela eqhubekayo.Ineenzuzo zomthamo onamandla wokuhambisa, umgama omde, isakhiwo esilula kunye nokugcinwa lula.Isetyenziswa kakhulu kwimigodi yamalahle, i-elektroniki, oomatshini, izinto zokwakha, iikhemikhali, amayeza, njl.

Ukusilela kweyunithi yokudluliselwa okubangelwa yenye

Ukusilela kwebhanti lokuhambisa

Ukungaphumeleli kwegubu

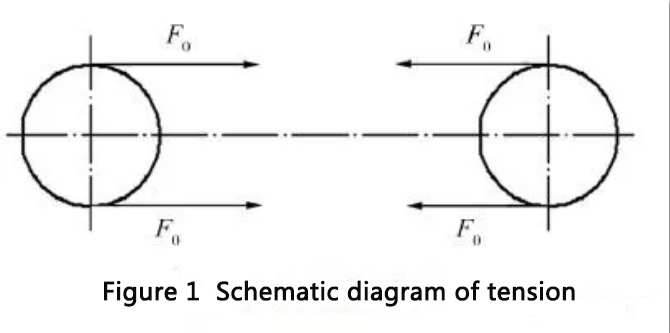

Kukho iintlobo ezine eziphambili zokungaphumeleli kwegubu.I-1 kwimveliso, ukunyanzeliswa kwebhanti ye-conveyor F0 kuya kuncipha ngokuthe ngcembe (jonga uMzobo 1), ukwenzela ukuba ukungqubuzana phakathi kwebhanti yokuhambisa kunye ne-drum kuncitshiswe, okubangela ukuba i-drum kunye nebhanti yokuhambisa ihambe;Ibhanti eli-2 lokuhambisa lizisa amanzi, udaka lwamalahle okanye i-oyile emdaka kunye nolunye udoti kwigubu kunye nebhanti lokuhambisa, elibangela ukuba i-roller kunye nebhanti lokuhambisa lityibilike;I-3 Umphezulu we-rubber ye-roller uhlanjululwe okanye ugugile, okubangelwa ukuhla kwe-friction factor, okubangelwa ukuhla kwe-friction phakathi kwebhanti yokuhambisa kunye ne-drum, ebangela ukuba i-roller kunye ne-conveyor belt iqhube;Ngaphantsi kwesenzo soxinzelelo lwebhanti yokuhambisa, i-roller shaft bearing inxiba kwaye iyaphuka, ibangela ukuba indawo yayo itshintshe, ibangele ukuba ibhanti lokuhambisa libaleke okanye i-roller kunye nebhanti lokuhambisa lityibilike, okubangela ukusilela komsebenzi.

Ukungaphumeleli kwe-roller

Kukho iintlobo ezintathu eziphambili zokungaphumeleli kwee-roller.1 Ngexesha lenkqubo yokusebenza, ukungqubana phakathi kwe-idler kunye nebhanti yokuhambisa kuveliswa.Ulwalathiso olusebenzayo lwebhanti yokuhambisa kunye nolwalathiso olujikelezayo lwe-roller lunombono othile wokuthambekela.Xa i-roller ijikeleza, ixhomekeke kumthwalo we-eccentric, obangela ukuba i-roller surface kunye ne-roller bearing.Ukugqoka kunye nokukrazula, njengoko ixesha lihamba, kubangela ukuba i-roller iphuke phakathi, i-roller yokujikeleza i-roller ayiguquki okanye ayijikelezi, kwaye nokuba i-bearing ikhutshwe, i-surface ye-roller kunye nesihlalo sokuthwala iyahlukana, kwaye i-welding iyasuswa, ngaloo ndlela ibangela ukuba ibhanti lokuhambisa liqhube.Ukutenxa, ukwanda kokumelana nomsebenzi kunye nokusilela kwezinto;I-2 ibhanti lokuhambisa lizisa amanzi, udaka lwamalahle okanye ioli engcolileyo kwindawo yokudibanisa ye-roller kunye nebhanti lokuhambisa, ukuze imveliso ingene ngaphakathi kwi-roller bear, ingcolise igrisi yokuthambisa, itshabalalise i-lubrication eqhelekileyo ye-bearing, kwaye ibangele. ukuthwala umonakalo;I-3 ukuhambisa Izinto eziphathekayo kwibhanti zixhomekeke kwelinye icala ukwenza umthwalo we-eccentric, kunye nomthwalo kwicala elingenamsebenzi we-roller liyenyuka, elikhawuleza ukunxiba i-roller surface kunye ne-roller bear, ebangela umonakalo kwi-roller kunye ne-roller. kubangela ukusilela emsebenzini.

Ibhanti yokuhambisa iyasilela ngenxa yokutshintsha kobubanzi begubu

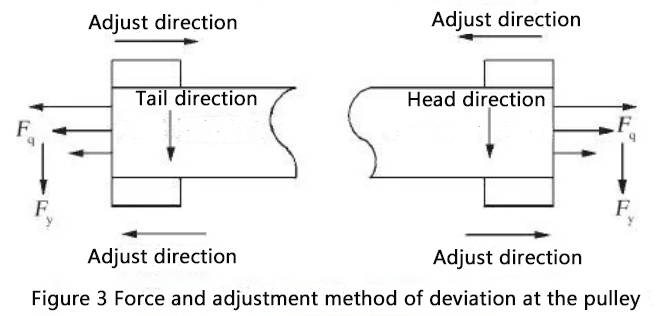

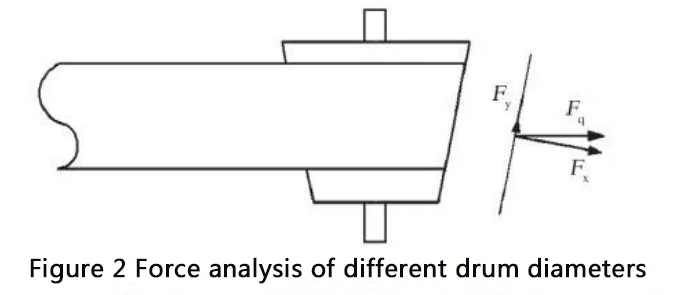

Ngenxa yempazamo yomatshini we-drum ngokwayo, umphezulu unamathele kwizinto eziphathekayo okanye ukugqoka okungalinganiyo kubangela ukuba ububanzi butshintshe.Amandla okutsala i-Fq yebhanti yokuhambisa yenza icandelo elishukumayo amandla Fy ukuya kwicala elikhulu ledayamitha yegubu.Ngaphantsi kwesenzo secandelo elihambayo lamandla e-Fy, ibhanti lokuhambisa livelisa i-roller ukuya kwi-roller.Xa ububanzi bukhulu, ibhanti yokuhambisa iya kunyuka ukuya kwindawo ephezulu, njengoko kuboniswe kuMzobo 3, kubangela ukuba umsebenzi ungaphumeleli.

Ukusilela okubangelwa kukugotywa kwebhanti lokuhambisa kwigubu

Xa ibhanti lokuhambisa lifakwe kwigubu, liya kugoba.Xa inani lokugoba lifikelela kumda walo wokudinwa, ukusilela ukugoba kuya kwenzeka.Ekuqaleni, iintanda ezincinci ziya kuvela.Ngokuhamba kwexesha, ukuqhekeka kuya kwanda okanye ukukrazula, okuya kuthi ekugqibeleni kubangele ukuba ibhanti lokuhambisa liphuke kwaye kubangele ukusilela komsebenzi.

Ukungaphumeleli kwe-roller

Ibhanti yokuhambisa ayisebenzi ngokufanelekileyo okanye ibhanti lokuhambisa lonakaliswe ngenxa yokunamathela komphezulu.

Ngenxa yempazamo yofakelo, iqela elithwele umthwalo linenguquko yesikhundla ngexesha lenkqubo yokuvelisa okanye umphezulu we-roller ubambekile ngeedipozithi ezifana ne-slime, enokubangela ukuba ibhanti lokuhambisa libaleke liye kwelinye icala kwiqela le-roller. iirola, ezikhokelela ekusilelekeni komsebenzi.

Ukusilela kwebhanti lokuhambisa okubangelwa kukonakala kwerola

Emva kokuba i-roller igqoke, i-metal surface iqhekekile okanye i-roller iphakanyisiwe phantsi komthwalo wempembelelo, ibangela ukunxiba okungaqhelekanga okanye ukukrazula kwebhanti yokuhambisa, okanye nokuba ikrazulwe, ekugqibeleni ibangele ukuba ibhanti lokuhambisa liphuke kwaye libangele ukusilela komsebenzi.Amanyathelo okuphucula, ukuhlolwa kunye nokugcinwa kwangexesha

Xa ibhanti lokuhambisa lixega kwigubu kunye nokutyibilika, ukunyanzeliswa kulungelelaniswa ngendlela yokunciphisa ubunzima, i-screw tensioning, i-hydraulic tensioning, njl., ukuphelisa impazamo yokutyibilika.Nangona kunjalo, xa ibhanti lokuhambisa likhubazekile ngokusisigxina, i-tensioning stroke ayonelanga, kwaye ibhanti lokuhambisa linokunqunyulwa ixesha lokujoyina kwakhona.

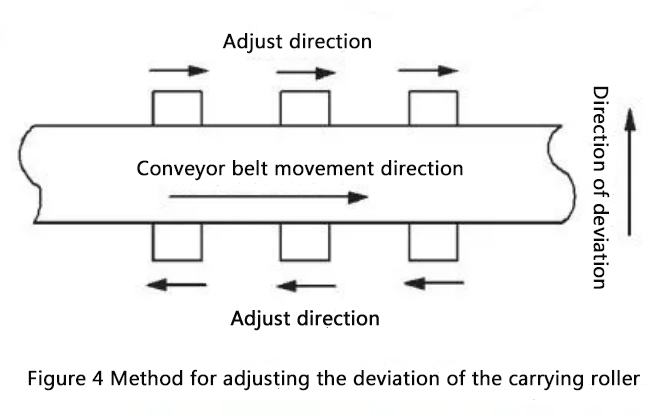

Xa kukho amanzi, udaka lwamalahle okanye ioli engcolileyo kumphezulu webhanti yokuhambisa, i-roller kunye ne-roller, kufuneka ihlambuluke ngexesha lokugcina indawo yokuhambisa yomile.Ukuba indawo engqongileyo imanzi, i-rosin inokongezwa kwigubu ukuthintela ukutyibilika.Ukuba umphezulu webhanti yokuhambisa uphazamisekile, i-rubber surface yombhobho yonakaliswe, kwaye i-roller ayisebenzi okanye yonakaliswe, kufuneka ilungiswe okanye ithathelwe indawo ngexesha.I-lubricant ethwele kufuneka icocwe kwaye izaliswe rhoqo, kwaye umsebenzi awukwazi ukuqhubeka ukuthintela iimpazamo ezininzi okanye iingozi zokhuseleko.Xa ukuphambuka kwenzeka, njengoko kuboniswe kuMfanekiso 2, isalathiso sentloko ye-roller ye-head drive njengoko iboniswe lutolo.Inxalenye engaphezulu yomgqomo ishukuma iye ekhohlo okanye isezantsi isiya ngasekunene.Ukugcina ukunyanzeliswa kwebhanti, isigubhu sikwindawo efanelekileyo.Isikhundla, umgqomo wokubuyisela umsila ulungelelaniswa kwicala elichasene nentloko ye-roller drive.Xa indawo ye-idler ingalunganga, indlela yokulungelelanisa njengoko kubonisiwe kwi-Fig 4. Leliphi icala lebhanti lokuhambisa elinotyekelo, leliphi icala le-roller iseti elihamba lisiya kwicala elifanelekileyo lebhanti lokuhambisa, okanye elinye icala. ithuthiwe.Ngecala elichaseneyo lohlengahlengiso lwentshukumo, kuyimfuneko ukulungelelanisa iiroli ezininzi ezikufutshane ekuphambukeni ukuze ugqibezele.

Amalungu othumelo afanelekile kwaye inkqubo ihlangabezana neemfuno.

Umgangatho weendawo zokuhambisa ezifana nebhanti yokuhambisa, i-roller kunye ne-idler kufuneka ifaneleke, kwaye ukungaphumeleli komsebenzi ngenxa yempazamo yokuvelisa i-drum ngokwayo akufanele kwenzeke.Inkqubo yokufakela kunye nokugcinwa kweendawo zokuhambisa ibhanti ihlangabezana neemfuno, kwaye impazamo ayikwazi ukudlula umgangatho.Isihambisi kufuneka sihambe kakuhle ukuthintela ukugcwala okanye ukothuka kwemithwalo.

Kwimveliso yangempela, kuyimfuneko ukuqinisa uxanduva lomqhubi webhanti kunye nabasebenzi bokuhlola, ukuphumeza ngokungqongqo ukusebenza komqhubi webhanti, iinkqubo zokuhlola kunye nokugcinwa, ukuhlalutya ngokucophelela kunye nokugweba iimpazamo ezifunyenweyo, kunye nokugcinwa ngexesha elifanelekileyo.Gwema ukwenzeka kweengozi ezinkulu, ukwandisa ubomi benkonzo yeendawo zokuhambisa ezifana namabhanti okuhambisa, iirola kunye neerola, kunye nokuphucula ukusebenza kakuhle kwemveliso.

Ixesha lokuposa: Jan-20-2023